| Afghan Energy, Chemical & Mining Industries resource for Renewable Energies, Irrigation & Sustainable Industries. |

sewage systemsWe can help in the following technologies encapsuling the area of Water Treatment and Sewage Systems Anaerobic Digestion of Organic Wastes – Process Parameters and Balances in Practicetable of average loadings and their equivalents >>>>>>>>>>> Activated sludge process >>>>>>>>>>>> Main sewage processes

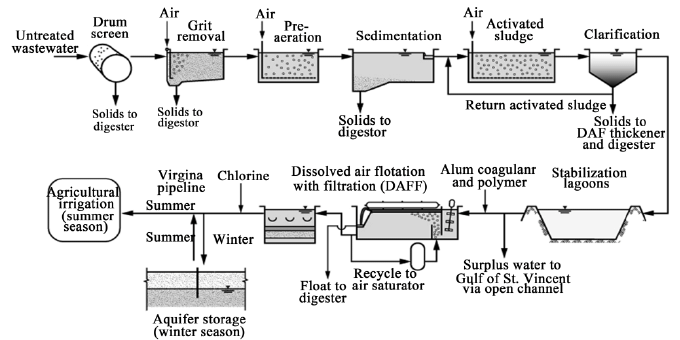

Diagrammatic representation of the process

of sewage treatment

Small-Scale Sewage Treatment Facility Diagrammatic representation of sewage

treatment at a small activated sludge plant There are various types of treatment Preliminary TreatmentIn most sewage treatment systems of any size there will be some form of Preliminary Treatment. In smaller treatment systems up to perhaps say 500 / 1000 population equivalent this stage may be omitted. There are several stages within the preliminary treatment section and these are - ScreeningThis stage removes all, large floating or suspended solids, rags, plastics, timber, animal carcasses. There are various types of screens from manual raked to mechanically raked. The subsequent screenings have to be dealt with in a suitable manner for removal off site. As an alternative it is sometimes possible to macerate the screenings to a much smaller size to be removed at later stages, but this may produce problems elsewhere. Grit RemovalThis stage which usually happens at larger works, removes as much as possible of the - silt, sand, gravel, cinders, ashes, metal, glass and even razor blades in the sewage. There are various types of grit removal systems from grit tanks, grit channels, and other mechanical systems. The grit once removed has to be dealt with in a suitable manner for removal off site. Flow MeasurementFlow of sewage to a works is measured to control and monitor treatment and to comply with consents. This can be undertaken by means of an open channel with perhaps a flume or V notch weir, or in a pipe with an external flow meter. Storm Water OverflowsAt some works where there is a high incidence of surface or storm water in the sewage (usually at works which serve older towns where the surface water readily enters the sewerage system) there is a need to separate the excess storm water flows out from the main sewage to be treated. This storm water may be by-passed to a separate storm overflow to the watercourse or may be stored in storm tanks, for later treatment once the main storm has passed. This separation is usually undertaken by means of storm overflow weirs. If there are to be storm storage tanks then these need to be carefully designed as some settlement will occur in the tanks. Primary SettlementPrimary settlement of the sewage is necessary to remove heavy solids, remove grease and scum, balance the load, and performs some biological activity. This is usually carried out by carefully designing tanks which are either of a, radial flow, upward flow, or horizontal flow type. The type of tank used will depend on many circumstances and it has to be carefully designed with all the many factors to be taken into account. From the primary settlement stage a lot of the coarser suspended solids will have been removed, and the biological content will have been reduced by between 25% and 50%. However from this stage there will be quite a lot of sludge which must be removed from the tank very regularly, and in a large works probably continuously. Sludge can be removed by means of, manual, automated systems, or by tank emptying. Biological TreatmentThe sewage after primary settlement still contains quite a large amount of biological pollutants. The aim of the biological treatment stage is to purify the settled sewage by removing dissolved organic material, so that, after further settlement, in humus tanks, the effluent can be discharged to a watercourse. Biological filtration is the oldest form of sewage treatment dating back to 1897. The process relies upon Aerobic Bacteria and Micro-Organisms to break down the impurities in the settled sewage. Other forms of life will also colonise the filter bed, for example, Protozoa, Worms, Fly and insect larvae, spiders, and even birds, each species feeding off smaller members in the food chain. To live and purify settled sewage the bacteria and micro-organisms need

Just like all human beings! In a good and correctly designed biological filter bed all these conditions can exist. A biological treatment system must however be correctly dosed with the sewage, and there are many different types of filtration system. Final or Humus SettlementFinal or Humus Settlement is usually carried out in tanks as they are a means of removing the smaller solids from filter effluent. Filter effluent contains quantities of biological film which has been washed from the media, dead micro-organisms and worms. These tanks are very similar in design to primary settlement tanks and can be either of a, radial flow, upward flow, or horizontal flow type. From this stage there will be sludge which must be removed from the tank very regularly, and in a large works probably continuously. Sludge can be removed by means of, manual, automated systems, or by tank emptying. The effluent from Humus Tanks will generally be about 90% to 95% clean, if the works are correctly designed and operated correctly. Tertiary TreatmentTertiary treatment is aimed at improving the quality of effluent produced by a conventional biological treatment plant. It is intended that tertiary treatment should polish a good quality effluent. It is not a substitute for inadequate secondary treatment processes. Tertiary treatment can achieve a reduction in

There are various types of tertiary treatment system, these being

The type of system to be used will depend on many factors and the designer will have to make a technical decision on which to use.

Vertical and Horizontal Beds SystemFlat Site

Sloping Site It is normal in the U.K. in a sewage treatment plant to achieve an effluent quality of at least the following quality:

Some plants offered may well achieve a higher quality of effluent. Table of Loadings for Sewage Disposal Facilities

Step-feed Anoxic/Aerobic Activated

Sludge System

1. Outline of equipment Recently, the problem of eutrophication of closed bodies of water is caused by the nutrient salts of nitrogen and phosphorus that can not be removed by such traditional methods as conventional activated sludge process without a large-scale renovation to the existing facilities. The step-feed anoxic/aerobic activated sludge process has been developed to enable efficient denitrification without a major renovation. 2. Features The step-feed anoxic/aerobic activated sludge process has the following features. 3. Performance (1) Design hydrological retention time: 8 hours 4. Applications

These modification will achieve high-efficiency nitrogen removal. If yet higher level of treatment is desired, we suggest adding an absolute anaerobic zone ahead of the reaction tank to biologically remove phosphorus, or installing movable bed type upward-flow continuous sand filter and flocculant dispensing unit downstream of final settling pond. This will carry out in-line coagulation filtration, removing phosphorus and SS.

Schematic Flow of Step-feed Anoxic/Aerobic Activated Sludge Process

Advanced Sewage Treatment System Using Low Pressure Reverse Osmosis 1. Purpose In recent years, reclaimed sewage has been used to supply ponds and streams in urban areas as a part of a multipurpose utilization program. The reclaimed water must be sanitary and safe for people to touch or even put into their mouths, when it is used for a city stream or pond. In response to those demands, Kobe Steel offers an "Advanced Wastewater Treatment System Using Low Pressure Reverse Osmosis" to produce clear, safe and sanitary water. 2. Performance Water Quality (Example of Analysis)

3. Characteristics 1) The low pressure reverse osmosis membranes remove color, odor, BOD, COD, MBAS (measure of foam-causing substance), N, P, bacteria, viruses, etc. Thus, very clear, safe and sanitary water is produced. Both the appearance and sanitary safety of the water is almost equal to that of tap water. 4. Principle 1) Pretreatment 5. Subject Streams, fountains and ponds for playing, bathing, keeping fishes, etc.

6. Figure Flowchart of the Advanced Wastewater Treatment Using Low Pressure Reverse Osmosis

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||